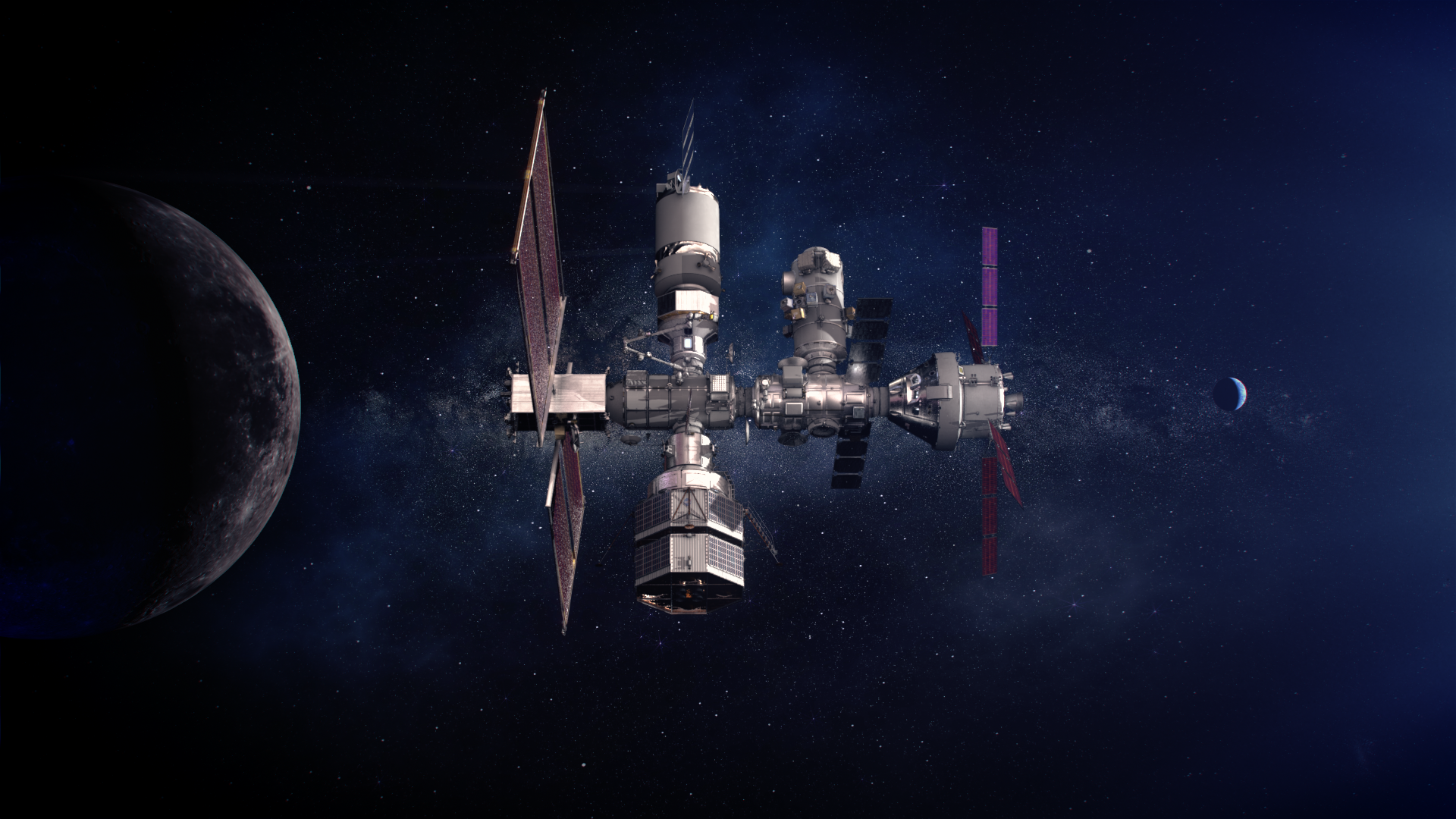

Cars need fuel, so do satellites and spaceships. However, the refuelling infrastructure on Earth is much better than in space. Or to put it another way: There are no refuelling stations in space. This means that the lifespan of satellites and the range of space ships depend primarily on the amount of fuel brought from Earth. To change this and enable sustainable exploration missions to more distant destinations in the future, ESA is contributing a special module to the planned Lunar Gateway space station: the "European System Providing Refuelling, Infrastructure and Telecommunications", or ESPRIT for short.

For aircraft, in-flight refuelling has been common practice for decades, at least in a military context; in space, such a project is still uncharted territory and represents a world first for some propellants. Experience to date has been limited to a few technology experiments and the refuelling of the ISS by ATV and Progress freighters as part of routine station operations – but the technology is of great strategic importance for crewed exploration missions to more distant destinations in the solar system. While going to the Moon is still relatively easy to accomplish with a single tank of fuel, interplanetary journeys are hardly possible without the possibility of refuelling. The reason for that? Fuel is heavy. Even on a mission to Mars, one of Earth's closest neighbouring planets, the mass of the fuel required can easily be more than half the launch mass of the spacecraft. If you then take landing and launch manoeuvres as well as the return to Earth into account, such a mission quickly becomes impracticable. Being able to plan the journey in several stages with refuelling stops would therefore be an absolute gamechanger.

Chemical propulsion, electric propulsion

To demonstrate refuelling in space and bring the technology to the maturity level needed for interplanetary travel, the Lunar Gateway space station will be used as a test environment. For attitude and orbit control, the Gateway will have two different propulsion systems: one is a chemical propulsion system and the other is a weaker but more energy-efficient electric propulsion system consisting of Hall-effect thrusters. As with other ion engines, Hall-effect propulsion works by ionising gas particles, which are then accelerated in an electric field to generate thrust and ultimately ejected in the form of a jet.

It is in fact the ion drive that will make it possible to achieve the ambitious research goals of the Artemis programme, because only with it can the Gateway be transferred between orbits in Earth-Moon space and stabilised in its target orbit, which is a so-called near-rectilinear halo orbit (NRHO). An NRHO is a highly eccentric orbit that on the one hand brings the Gateway close to the Moon, but on the other hand also allows it to make wide loops at a greater distance. The advantages of this orbit are obvious: at the point closest to the Moon, the Gateway can easily be approached by lunar shuttles, and at the point furthest from the Moon, transporters from Earth can dock without much effort. In addition, in an NRHO the Gateway never disappears completely behind the Moon, which facilitates radio contact with Earth.

To extend the life of the Gateway in lunar orbit, refuelling is provided for both types of propulsion systems used. Accordingly, the station needs two different refuelling systems: one for refuelling the chemical engine with hydrazine and another for refuelling the ion engine with xenon. The former is being contributed under the name "Bipropellant Transfer System" (BTS) by Thales Alenia Space in the UK, the latter is being developed as "Xenon Transfer System" (XTS) by OHB in Bremen. Both systems will eventually find their place in the "European Refueller Module" (ERM), which in turn is part of the ESPRIT module.

Xenon – the foreign gas

Xenon is a monatomic colourless and odourless gas. When it was discovered by two English chemists in 1898, it was the rarest of the known noble gases. This fact is directly reflected in its name, which is based on the Greek word "xénos" for "stranger". Xenon is very well suited as a fuel for ion drives as it requires relatively low ionisation energies, is non-toxic and also inert, which means that the metallic components of the drive corrode little or not at all. In the first experiments with ion drives in the 1960s, caesium or mercury were still used as propellants, which caused massive corrosion.

Nevertheless, the development of the XTS is anything but simple. The flow rate, pressure and temperature of xenon are closely coupled, which means that extreme temperature fluctuations can occur during an unregulated refuelling process. It is possible to transfer xenon from one tank to another without sophisticated technology, but this would take several months, as the gas tends to heat up dramatically if transferred too quickly.

OHB and the XTS

To avoid this uncontrolled heating, the heart of the XTS consists of a thermal compressor. This takes in the gaseous xenon and first cools it down to such an extent that it partially liquefies. Once sufficient liquid xenon has accumulated, it is heated again. This causes it to expand, evaporate and the pressure increases. When a certain pressure is reached, a valve is opened and the compressor discharges. The process does not sound too complex in theory, but in practice it requires an extremely complicated set-up of valves with different functions, filters, pressure and temperature sensors, a heat exchanger and much more. Some of the required parts still have to be brought to the necessary technological maturity, others are already being mass-produced.

The strategy is clear: the ESPRIT team works step by step and builds XTS models of increasing complexity – starting with a so-called breadboard, which mainly consists of components that are not yet space-worthy. Only after testing a more complex model with components that have already been further developed does the production of the actual flight model begin. The ERM, for which Thales Alenia Space in France is responsible and to which OHB is contributing not only the XTS but also the unpressurised structure, is then to be brought to the Gateway on NASA's Artemis 5 mission (officially Artemis V) accompanied by a crew of four and docked there. The timetable? A launch in 2028.

The bigger picture

With the development of the XTS, OHB is not only supporting the progress of research and science but also NASA's stated goal of a sustainable lunar campaign and the testing of technologies for a first human flight to Mars. While many components of the Gateway architecture simply provide infrastructure that already exists in this or a similar form on the ISS, the XTS represents an absolute novelty – and could ultimately also enrich the satellite business as a spin-off. Electric propulsion systems are also popular in commercial near-Earth applications. Sustainability is also an issue here and refuelling satellites is not an unattractive idea.

Read more about the Lunar Gateway and the Artemis missions in Part 1 of our story.