Since 1 January 2021, OHB has been part of the EASI-STRESS project funded by the EU under Horizon 2020. The aim of the project is to develop standards for the non-destructive analysis of residual stresses in components. OHB has been working intensively on this topic since 2018 and is representing the interests of European aerospace and the German industry in the project consortium.

In this interview, project manager Axel Müller and Roland Schneider and Marco Mulser from technology coordination explain why residual stresses in components are a problem, how they can be analysed and at what stage the EASI-STRESS project is.

What is the EASI-STRESS project about? What is the objective?

Axel Müller: EASI-STRESS is a project funded by the EU under Horizon 2020. The project aims to validate non-destructive testing methods for characterising residual stresses in metallic materials against destructive analysis methods and to develop standards. By involving industrial partners, the step towards process development and quality assurance in industrial settings is to be completed.

Roland Schneider: So far, non-destructive testing methods for determining residual stresses are not very widespread. We want to change that with EASI-STRESS.

What are residual stresses and why is it important to characterise them?

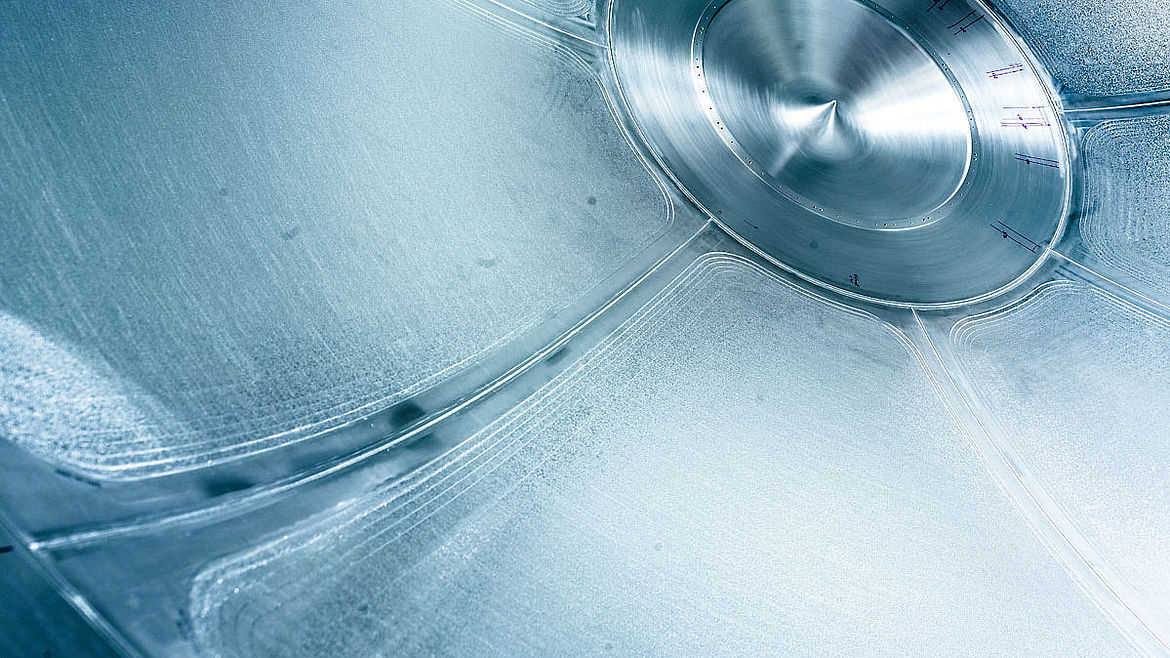

Marco Mulser: Residual stresses are mechanical stresses that occur in a body without external forces acting on it. They are distortions in the structure of the material, which can weaken the component. In metallic components, such stresses are usually caused by thermal and mechanical manufacturing and joining processes, for example during welding, milling, casting or even 3D printing. From the outside, the residual stresses are invisible, but they have a decisive influence on material fatigue and can even lead to catastrophic material failure.

How can residual stresses in components be determined?

Axel Müller: Residual stresses are an intrinsic quantity. This means that they cannot be measured directly. You can only measure other variables and then derive the residual stresses from them. And to measure these variables, you have the choice between destructive and non-destructive measuring methods. Currently, the most commonly used method for measuring residual stresses is the hole drilling method. This is a destructive method in which a small hole is drilled into the component. The removal of material disturbs the existing stress equilibrium at the measuring point and triggers deformations in the material. The original residual stress can then be determined from these deformations. The decisive disadvantage of this method is of course the destruction of the component through the drilling of a hole. This is one of the reasons why the EASI-STRESS project is looking into non-destructive analysis methods, focusing on synchrotron and neutron-based diffraction techniques. Diffraction techniques use different types of radiation to measure microstructural imperfections such as lattice distortions in the material. These can then be used to draw conclusions about the residual stresses and their directional dependence.

What are the advantages of non-destructive testing methods?

Roland Schneider: First and foremost, they have the advantage that they do not destroy the component to be tested and thus measurements can be carried out on components that are intended for actual use. In addition, the residual stresses prevailing in the material can also be visualised three-dimensionally.

Axel Müller: The fact that the testing does not destroy the component opens up completely new investigation possibilities. For example, you can examine components before and after environmental tests, map fatigue processes over time or directly evaluate stress-reducing measures.

Which non-destructive testing methods are being investigated in the EASI-STRESS project?

Marco Mulser: The aim of the EASI-STRESS project is to establish synchrotron diffraction and neutron diffraction as additional methods for determining residual stresses in metallic components. Compared to X-ray diffraction, these two methods have the advantage that a greater penetration depth can be achieved and complex geometries can also be investigated.

What does the EASI-STRESS consortium look like?

Axel Müller: We have close cooperation between science and industry. The EASI-STRESS consortium consists of fifteen partners, including several major research institutions with access to particle accelerators and representatives of various industries. EASI-STRESS is an EU project, so the consortium is also European. OHB represents the European aerospace sector and German industry. However, there are also companies from the mobility and energy sectors involved. The project is coordinated by the Danish Technology Institute in Aarhus.

What does the work in the EASI-STRESS project look like in practice?

Axel Müller: The project has several sub-goals, which in the end come together to form the overall goal mentioned at the beginning. An important step is that the methods of synchrotron and neutron diffraction are validated against the established destructive methods by measurements on different test specimens. In addition, interlaboratory tests have already been started to compare the results obtained on different test stands. In order to arrive at a standard procedure, it is important that the results obtained by different research institutions and working groups are comprehensible and, above all, reproducible.

Marco Mulser: To ensure that this is the case, standardised processes for sample preparation, test performance and data processing are to be developed as part of EASI-STRESS. And the format in which the data is exported is also to be standardised. This will ensure that the results obtained from measurements are actually helpful for science and the industry and can be used, for example, to validate simulations.

What role is OHB playing in this?

Axel Müller: The EASI-STRESS project aims to support industry in analysing and improving its materials in the best possible way. Of course, this also means that industry has to specify its requirements. OHB represents the European space industry and contributes practical experience. For which components is it particularly important to know the residual stresses? Where have there been cases of damage in the past? Where can the greatest added value be achieved through non-destructive testing methods? These are the questions to which we have the answers.

Marco Mulser: And these answers naturally result in concrete requirements for the measurement processes, which we communicate to the consortium. Overall, we hope that at the end of the EASI-STRESS project we will have the appropriate tools and processes to better predict stresses in components. Then we could already take these into account in the design and thereby possibly save material and thus weight, for example in the design of components in 3D-printing. In addition, precise knowledge of stresses can help to qualify new materials or processes more quickly.

Axel Müller: OHB has already carried out its own measurement campaigns in 2018 and can draw on this experience for EASI-STRESS. At that time, 3D-printed components and stresses that occur along weld seams, among other things, were analysed using diffraction methods.

What is the current project status?

Axel Müller: The project has been running since 1 January 2021 and ends on 31 December 2023. The first round robin tests were started before Christmas. In 2022, the test specimens will be examined by the working groups at the various research institutions with different synchrotron and neutron instruments and the data will be evaluated individually. In parallel, additional measurements will be carried out on industrially relevant materials and geometries. We are highly interested in the outcome of these experiments because the test specimens were designed to replicate various industrial forming and processing procedures. In a later phase of the project, these processes will also be investigated on real components using case studies defined by the industrial partners. At this point, we will of course also bring real aerospace components into play and are already looking forward to the results.