Digitalization is already commonplace in many aspects of logistics. Satellite data is also often used for this purpose. A good example of this is online shopping, where we can track our parcel in real time and see the current location of our order on our smartphones. In many parts of logistics, however, there is still scope for improvement and many processes could be made more efficient. This is also demonstrated by the project "Digital Twin" initiated by OHB subsidiary OHB Digital Services GmbH, which is transforming conventional logistics into smart, digital logistics at the port of Bremen using satellite data as a basis.

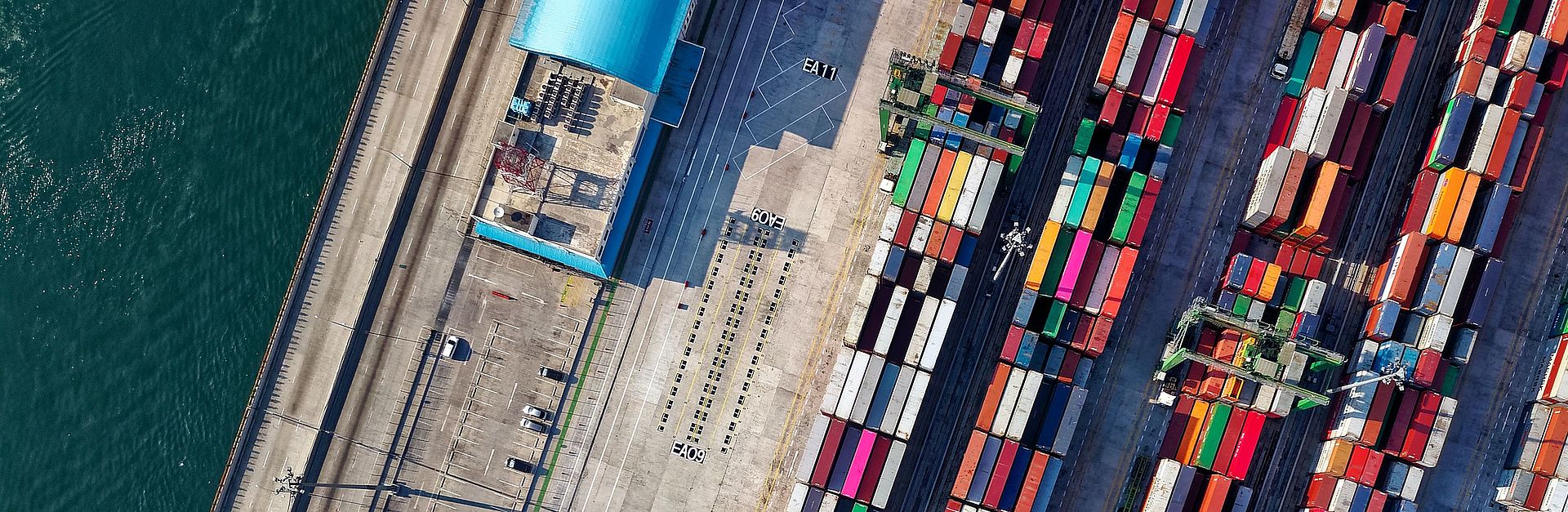

Rhenus Weserport operates four terminals covering an area of more than 330,000 square meters at the port of Bremen. Among other things, steel coils (coils made of steel strip) are temporarily stored for onward transportation for use in the automotive industry for example. Until now, the logistics processes have been implemented free of any digital support: The steel rolls must be labelled by hand and some of them marked in color so that they can be distinguished. This approach is very prone to errors and inefficient and ties up a great deal of time and personnel. This is why a project was launched in spring 2020 with the aim of making these processes more efficient. In this joint project, Rhenus Weserport, OHB Digital Services GmbH, Bremen-based IT company UbiMax and the University of Bremen are addressing one of the central challenges facing logistics companies today: the digital transformation of business processes.

Virtual twin for logistics

The large amount of manual work that is still required by Rhenus Weserport results in a high error rate and severe inefficiency. In order to rectify this, the company will be working with a digital twin provided by OHB Digital Services GmbH in the future: The warehouse storing the steel coils, together with all relevant buildings and objects, is digitally replicated on a one-for-one basis and mapped virtually in three dimensions to create a Digital Twin of the business processes. This results in full transparency and improved control of the processes. The digital twin is created using a combination of artificial intelligence, smart sensors and GNSS satellite data. This is highly accurate navigation satellite data with a positioning accuracy to two centimeters.

What is a Digital Twin?

A digital twin is a virtual real-time copy of certain aspects of the real world. It has the same characteristics as its real-world counterpart. The digital twin updates itself as it is continuously connected to the physical object it represents. It consists of sensors that receive data, a memory, and software that links all this data. Digital Twins can boost efficiency and improve logistics processes across the entire logistics industry: Processes become transparent, security is heightened, the error rate is minimized and rapid adjustments can be made, while the whole process does not require high financial or personnel resources. This is why Rhenus Weserport is using a digital twin provided by OHB Digital Services.

Indirect tracking saves the need for additional resources

Objects are usually equipped with expensive chips so that they can be tracked. For this purpose, each individual object must be fitted with a chip. At Weserport, the process will be more efficient in the future: This is because the lifter that moves the steel coils - rather than the steel coils themselves - is fitted with sensors and tracked. Four sensors are attached to each lifter. The sensors and GNSS data can be used to accurately determine when and where the lifter has picked up, moved and deposited a steel coil.

“This method lowers resource requirements by 20-30 percent. We don’t have to procure and install trackers and the processes are much cheaper and faster, making them far more efficient. The use of satellite data combined with smart algorithms is a solution that works,” explains Dr. Arne Gausepohl, Managing Director of OHB Digital Services GmbH.

Forward-looking methodology

This method – the use of a digital twin combined with indirect tracking – can be taken one step further. The technology used can be easily retrofitted, while individual processes can be taken into account and implemented cost-effectively. Here at Weserport, where this procedure will be used from spring 2021, the individual steel coils could, for example, also be automatically detected or the lifters could move and lift objects fully automatically (currently, this is still being done by trained staff).

In principle, however, this method can also be applied to other areas outside port logistics: At construction sites, airports, warehouses, external storage areas, etc., knowledge derived from space travel can be used to control processes with satellite support. As Rhenus Weserport shows, satellites can help to implement the digital transformation and optimize logistics processes.

About OHB Digital Services GmbH

OHB Digital Services GmbH forms part of OHB Digital, the OHG Group’s third division. For more than 30 years, close to 50 software developers, security experts, UX designers, software testers, software architects and project managers have been designing and implementing smart IT solutions and directly applying knowledge derived from space technology.