Bremen, 3. November 2022. MT Aerospace AG has signed a contract worth 35 million euros with ArianeGroup GmbH for the further development of demonstrators for CFRP upper stages of European launch vehicles. ArianeGroup with MT Aerospace were awarded the contract by the European Space Agency (ESA) to continue the development of the PHOEBUS (Prototype for a Highly OptimizEd Black Upper Stage) project. With the help of the PHOEBUS technology demonstrator, a lightweight composite upper stage* based on carbon fiber will be developed for the new European launch vehicles. In the PHOEBUS technology development project, MT Aerospace is focusing on complete CFRP solutions: The use of the smart material carbon fiber makes it possible to largely dispense with metallic components of the upper stage tanks and structures. This reduces mass, increases the payload capacity of the launch vehicles, reduces the use of resources and thus decisively improves the competitiveness of future launch vehicles. MT Aerospace and ArianeGroup will test and validate PHOEBUS in two phases until mid-2023 and 2025. The current contract continues MT Aerospace's long-standing and successful collaboration with ArianeGroup. It follows contracts signed in 2019 and 2021.

The 'black upper stage' for the next generation of European launch vehicles will be made of ultra-light composite materials. Carbon fiber technology is leading the way for future space transportation concepts. "MT Aerospace is thus achieving technology leadership in Europe and will develop new products from it. This opens up new and global growth opportunities for the Augsburg site and is an important milestone for our corporate development," explains Ulrich Scheib, MT Aerospace's Chief Programs Officer.

Reducing mass, increasing payload capacity and making aerospace more sustainable

The use of carbon fibers will sustainably reduce the weight of the upper stage. PHOEBUS* is a key element in the development of ICARUS (Innovative Carbon ARiane Upper Stage). PHOEBUS is made of carbon fiber-based composites, rather than metal, which saves weight and has a positive impact on the cost of each rocket launch. This allows more payload capacity (e.g., satellites) to be carried into space: Each rocket equipped with a black (named after the dark material CFRP) ICARUS upper stage will be able to carry up to an additional two tons of payload on board. This will contribute to a more sustainable use of resources.

"The development of the new upper stage will also pave the way for future technologies in the field of cryogenic applications and for possible uses of liquid hydrogen in aviation and other sectors," explains Hans Steininger, CEO of MT Aerospace AG. "Our successful collaboration with ArianeGroup proves time and again that we are competitive and can turn European launchers into sustainable space champions. It fills us with pride that, as the largest systems partner for the Ariane program, we are leading the way in developing concepts for future-proof space applications and helping to ensure the sustainability of space travel."

Exploiting the potential of the smart material CFRP

Over five decades, MT Aerospace AG has been able to build up a valuable wealth of experience thanks to various development contracts from European launchers and commissioned series production. CFRP also opens up new possibilities in the manufacturing process: For example, the use of CFRP allows for an integrated design, which means that there are fewer individual components than with a metallic counterpart, whose individual components cannot be manufactured in a single production process but have to be welded or assembled together downstream. This has a further positive effect on product costs.

Making lightweight construction easy: the automated fiber placement process as a core technology

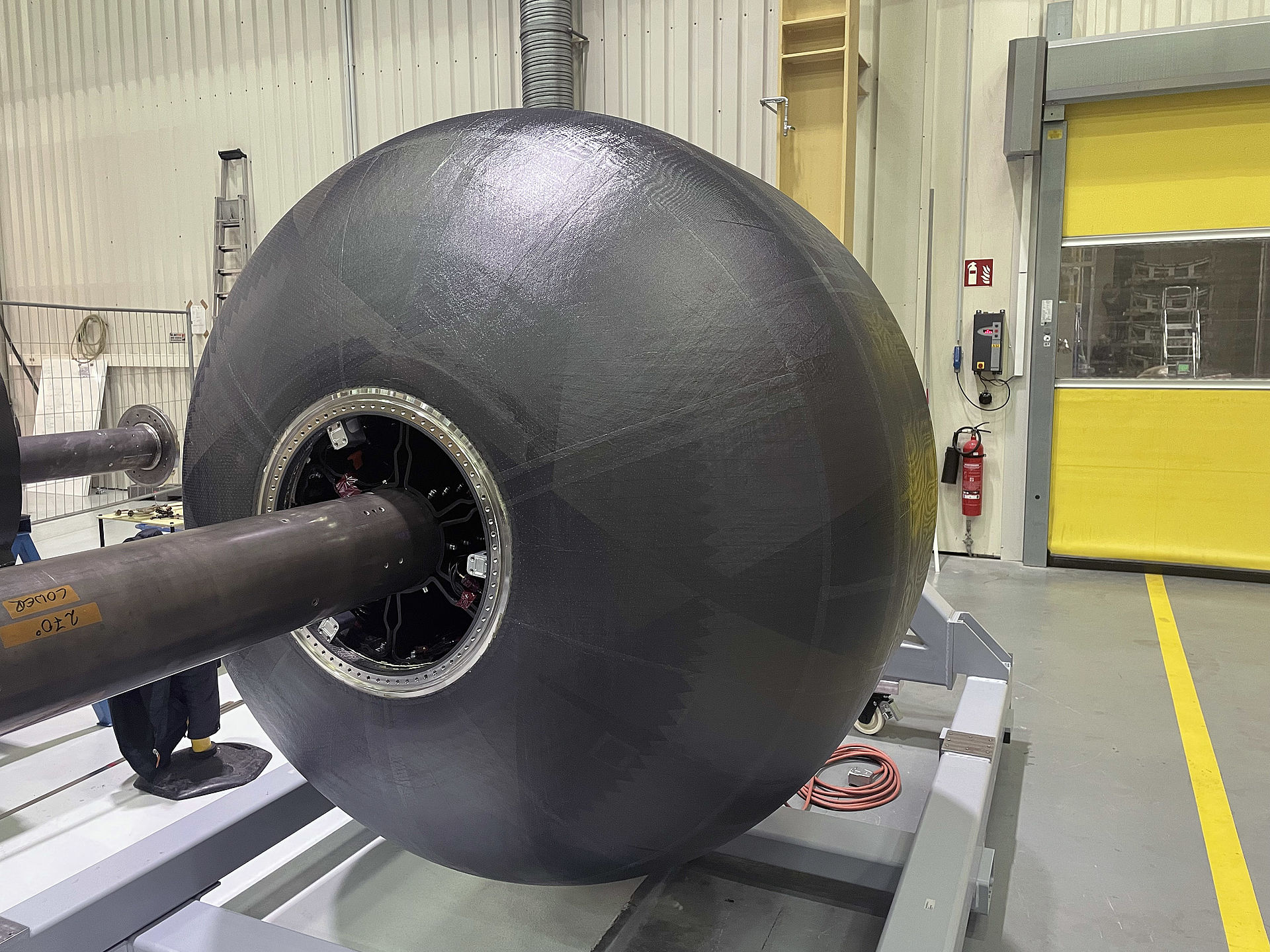

MT Aerospace AG is one of the leading companies in lightweight construction from metals and composites and has been active in the aerospace industry for decades. Here, every gram often counts. It also depends on maximum precision and reliability, reproducibility and compliance with international standards. The transition from metallic to composite materials represents a paradigm shift in upper stage design and production. With its new AFP (Automated Fibre Placement) facility, MT Aerospace is laying an important industrialization foundation stone for the optimized upper stage of carrier systems. The AFP process represents the core technology for the future composite products required for the black upper stage in the form of tanks and structures.

PHOEBUS project benefits from expertise in space tank systems

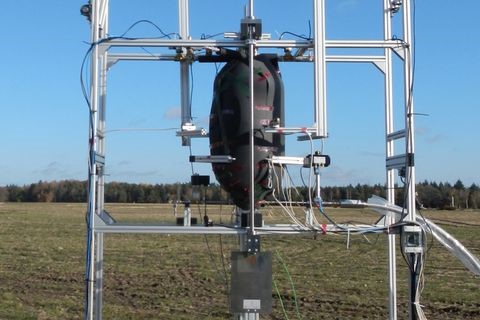

MT Aerospace has worked closely with ArianeGroup to develop technologies for the design and construction of cryogenic tanks and associated carbon fiber structures. The company has the expertise to produce carbon fiber structures and tanks up to 3.5 meters in diameter. "Having demonstrated the properties and reliability of our CFRP cryogenic fuel tanks at the smallest scale level, we are now entering a new phase, demonstrating performance in two steps up to the full-scale level. We are thus laying the foundation for subsequent 'black top' product development," says Thomas Schnaufer, Head of Launcher Composites & Composite Technologies, summarizing the benefits.

Quality first - developing, testing and evaluating

The German Aerospace Center (DLR) will evaluate the performance of the PHOEBUS demonstrator with cryogenic hydrogen and oxygen at its test center in Lampoldshausen, Germany. The PHOEBUS project is part of the ESA Directorate for Space Transportation's Future Launchers Preparatory Program. ArianeGroup, together with MT Aerospace, will develop, build and test the PHOEBUS carbon fiber composite demonstrator in two phases. The project will initially progress to mid-2023 with the construction and testing of the "Technology Control Vehicle," a scaled-down version with a diameter of two meters, to demonstrate the manufacturing processes. Subsequently, ArianeGroup will use MT Aerospace components to assemble and test the PHOEBUS demonstrator; the demonstrator consists of a liquid hydrogen tank mounted on a liquid oxygen tank and has similar dimensions to parts of the future carbon fiber upper stage. Final tests, which will include the filling and refueling cycle, tank pressurization and depressurization, will be conducted at DLR's Lampoldshausen test center in southern Germany toward the end of 2025. This will be the world's largest carbon fiber cryogenic tank demonstrator to date.

*) PHOEBUS stands for "Prototype for a Highly OptimizEd Black Upper Stage" and is the main element for the development of ICARUS ("Innovative Carbon ARiane Upper Stage").

*) Rocket upper stage: In the development of the future "Black Upper Stage", MT Aerospace AG is foreseen with the tanks for liquid hydrogen and liquid oxygen, including the associated structures. In conjunction with the components supplied by ArianeGroup, such as the multiple ignitable Vinci engine and the various fluidic, hydraulic and electronic monitoring and control systems, this system also integrated by ArianeGroup forms the travel platform for the satellites into space before they are separated from the upper stage and have to reach their destination under their own power.

Contact for media representatives:

Marianne Radel

Head of Corporate Communications

Phone: +49 421 2020 9159

Email: marianne.radel@ohb.de

Contact for investors and analysts:

Marcel Dietz

Investor Relations

Phone: +49 421 2020 6426

Email: ir@ohb.de