Bremen/Oberpfaffenhofen, September 13, 2018. Little brother’s got some moves: OHB System AG, a subsidiary of listed space and technology company OHB SE, together with the Fraunhofer Institute for Production Engineering and Automation IPA, has designed a mobile and certified mini clean-room cover for protecting particularly sensitive products in clean-room facilities. Known as the µCAPE® , it is the smaller version of the CAPE®, which has been on the market for several months.

“Our µCAPE ® is ideally suited for protecting sensitive hardware in a high-purity-class clean room while no direct work is being carried out on it for a foreseeable period of time or if the activities to be performed expose the surroundings to the risk of contamination,” explains Dr. Axel Müller, OHB System AG’s Cleanliness Officer. “A certified and space-saving solution is required to protect products or measurement equipment in clean rooms swiftly and effectively,” Müller adds.

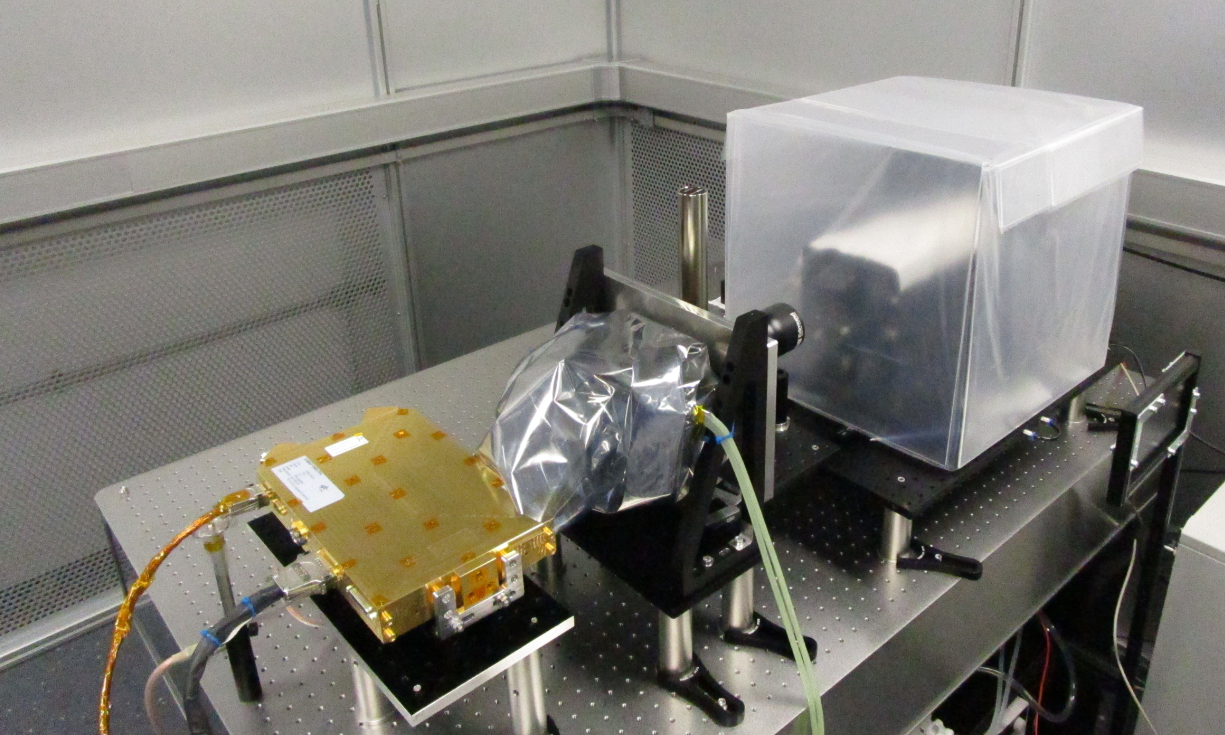

In developing µCAPE®, the team were able to leverage the expertise, measurement instrumentation and validation of its big brother, the CAPE® solution, a flexible certified textile clean room. A prototype was developed together with OHB’s partner Fraunhofer IPA in Stuttgart. After lengthy measurements of materials, a stable foldable cover made of ultra-pure film was engineered and can be fabricated in accordance with customer specifications. The µCAPE® is a well documented and certified solution thanks to the ease with which it can be set up and the measurable reductions in the risk contamination (cover protection against particulate and molecular external contamination) according to Dr. Axel Müller.

With the µCAPE®, it is possible to protect hardware on an area of about 5 x 5 cm² to 1 x 1 m² in the shortest possible time and to store the protective device within easy reach. In addition to the space industry, OHB and IPA also see potential in the pharmaceuticals, optics, food, medical and semiconductor industries wherever customers require documented protection of hardware or measuring equipment or for quality assurance purposes.

Testing successfully completed

µCAPE® was used for the first time in an ISO5 clean room at OHB’s Space Center “Optics & Science” at the beginning of 2018. “The system not only worked perfectly but also showed potential for other applications and extensions,” says Dr. Müller, going on to say that “µCAPE® was implemented by IPA extremely professionally. It is increasingly becoming the standard for OHB projects. Contamination loads can be estimated more realistically and duly lowered, thus reducing the effort required and improving performance. Risks and time estimates in normal and special activities are minimized for this standard solution and its availability.”

Companies interested in buying µCAPE® are welcome to contact OHB System AG or IPA Fraunhofer Stuttgart.

Information on its big brother, the CAPE®, can be found in our press release of February 6, 2018.

https://www.ohb.de/en/news/partnership-between-ohb-and-fraunhofer-ipa/

Contact for media representatives:

Marianne Radel

Head of Corporate Communications

Phone: +49 421 2020 9159

Email: marianne.radel@ohb.de

Contact for investors and analysts:

Marcel Dietz

Investor Relations

Phone: +49 421 2020 6426

Email: ir@ohb.de