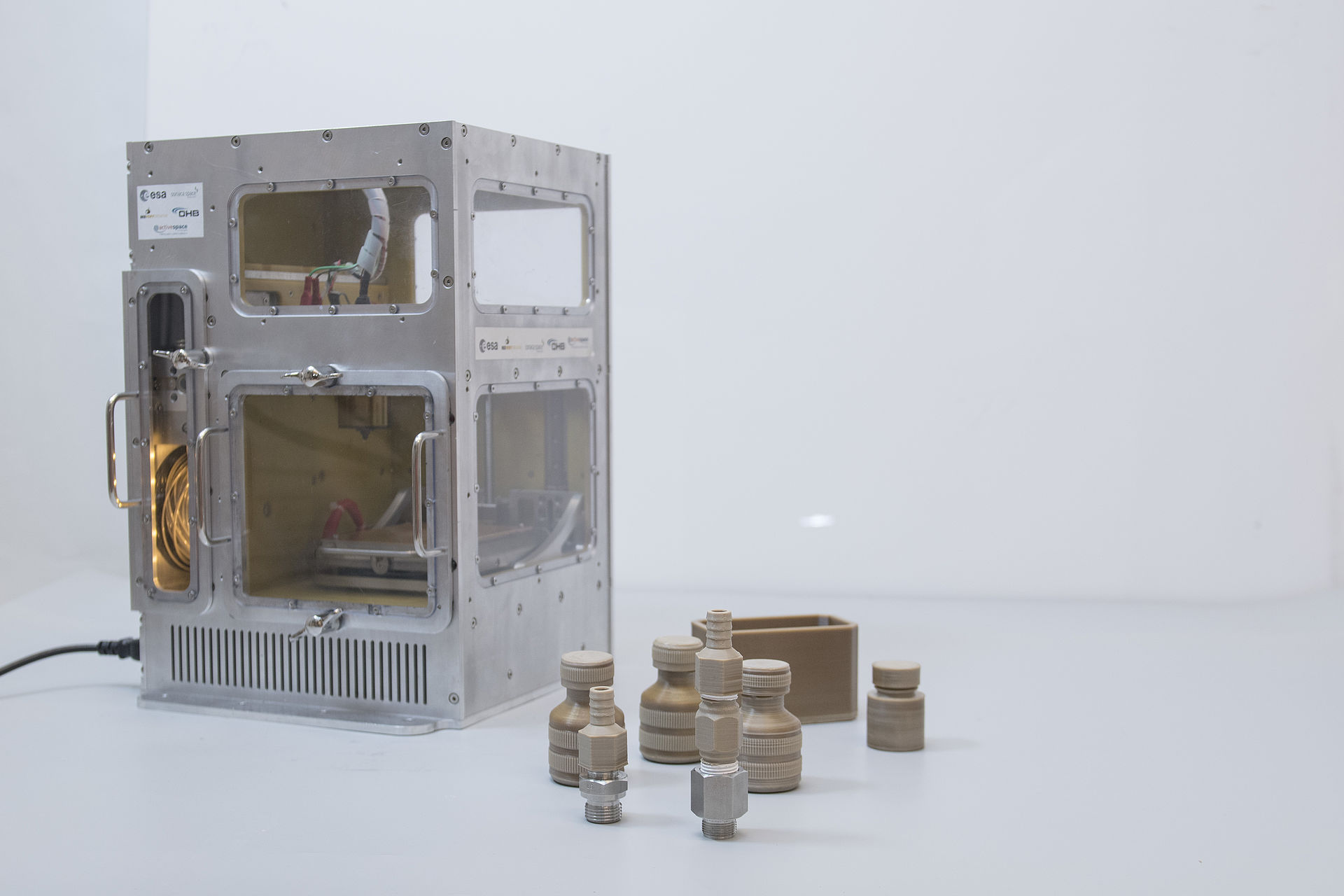

Bremen, January 21, 2019. OHB System AG, a subsidiary of space and technology group OHB SE, signed a contract with the European Space Agency ESA for the development of a 3D printer prototype suitable for large part production using high strength and functional thermoplastics and designed to meet the requirements for accommodation on the International Space Station (ISS). OHB is leading a consortium with three other European entities; the German space company Sonaca Space GmbH, BEEVERYCREATIVE, 3D printing company from Portugal and Athlone Institute of Technology in the Republic of Ireland. The project is called IMPERIAL.

The goal of the awarded activity, called IMPERIAL, is the design, development and testing of a fully functioning printer model meeting the requirements for additive layer manufacturing on-board ISS, using engineering thermoplastics and alleviating build volume constraints. In order to demonstrate the functionality of the printer, several functional parts need to be selected, printed and tested. The printed parts shall demonstrate the capability of in-space manufacturing to enable new maintenance and life support strategies for human space flight.

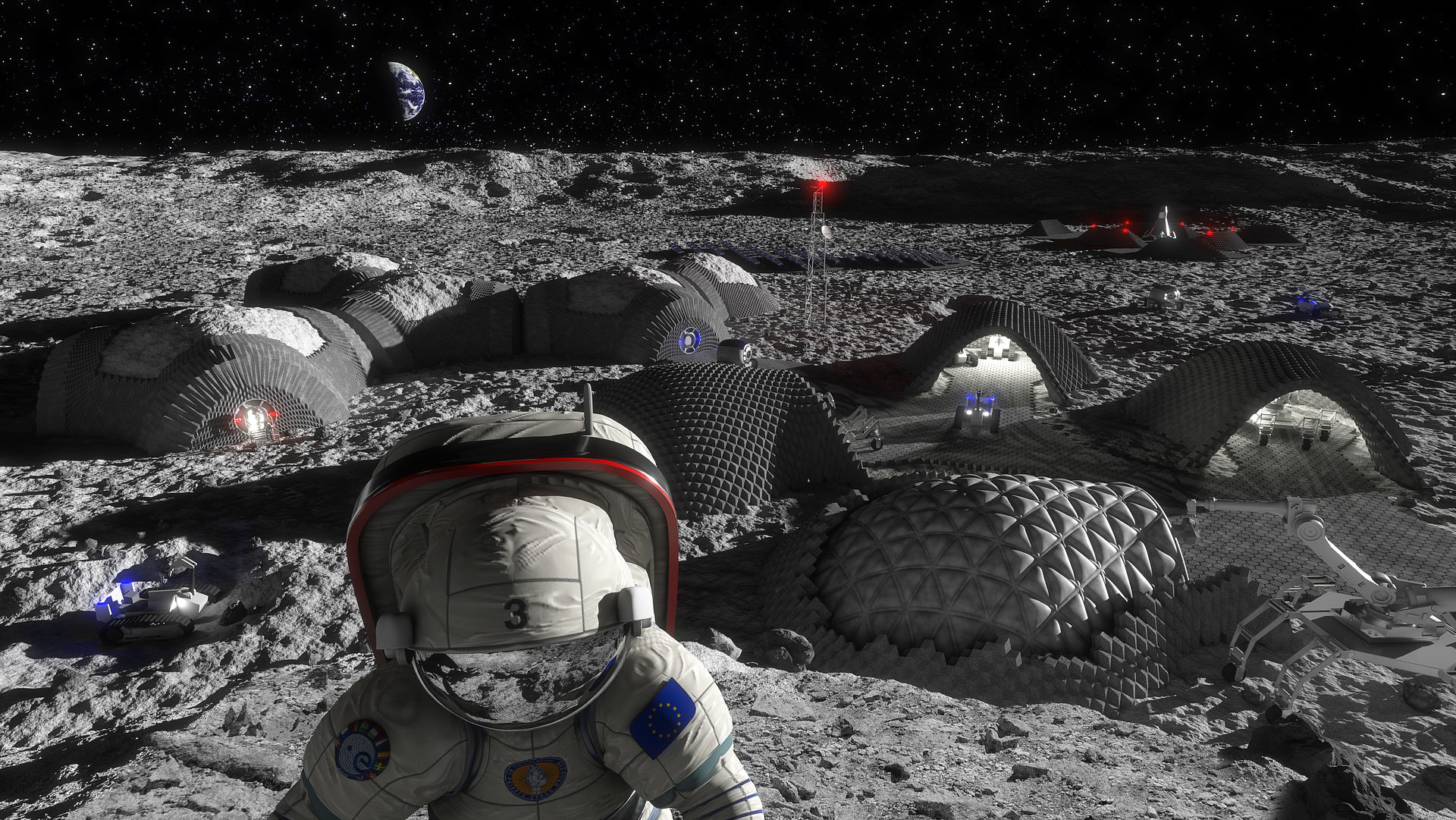

For the past 3 years, the Human Spaceflight department at OHB System, has been strongly involved in Space 3D printing applications and technology adaptation with ESA. In particular, with the recent study about conceiving a Lunar Base using 3D printing technologies called URBAN and Project MELT (Manufacturing of Experimental Layer Technology) project. Both of these projects demonstrated the major benefit of additive manufacturing in the broadness of design options it allows.

About OHB System AG

OHB System AG is one of the three leading space companies in Europe. It belongs to the listed high-tech group OHB SE, where around 2,700 specialists and system engineers work on key European space programs. With two strong sites in Bremen and Oberpfaffenhofen near Munich and more than 35 years of experience, OHB System AG specializes in high-tech solutions for space. These include small and medium-sized satellites for Earth observation, navigation, telecommunications, science and space exploration as well as systems for human space flight, aerial reconnaissance and process control systems.

About BEEVERYCREATIVE

BEEVERYCREATIVE is an SME Portuguese private company recognized for their quality, design and easy to use solutions. The company’s core business is to develop, produce and sell desktop 3D printers for their own portfolio and special additive manufacturing projects on demand. BEEVERYCREATIVE is proud of seizing close relationship with very significant companies and scientific entities, as for example, the partnership with SIEMENS in several fronts which include the i.experience centres created to foster students and incubated start-ups knowledge and experience software and equipment of both companies.

About Sonaca Space GmbH

Sonaca Space GmbH is a Space Engineering company part of the Sonaca Group. The company (formerly Active Space Technologies GmbH), with ca. 20 employees, has a decade of experience in Thermo-mechanical, Structural Engineering and R&D, Testing, Product/Quality Assurance. Part of the Sonaca Group since 2016, it was established primarily as a thermal engineering company in 2007 and after almost ten years solid growth was acquired by Sonaca, allowing the Group to provide complete Thermo-mechanical solutions to the market, with a focus on thermal and structural subsystems, mechanisms, GSEs and R&D. Sonaca Space GmbH (SSG) now has 600-m² premises in Berlin with in-house developed Thermal Vacuum Chambers, Ambient Pressure Thermal Cycling Chamber, and Thermal Characterization unit.

About Athlone Institute of Technology

Athlone Institute of Technology (AIT) is a modern Higher Education Institution that combines excellence in teaching with cutting edge technology and facilities. AIT has been providing undergraduate education in polymer materials and processing since the 1970s and hosts the APT Technology Gateway centre, a dedicated applied polymer research department which specialises in the design, processing and testing of polymer materials for medical device, automotive and aerospace applications. The 9000 sqm facility is equipped with cutting edge polymer processing facilities, a state of the art polymer characterisation and testing suite, in addition to a dedicated polymer part and tooling design function.

Contact for media representatives:

Marianne Radel

Head of Corporate Communications

Phone: +49 421 2020 9159

Email: marianne.radel@ohb.de

Contact for investors and analysts:

Marcel Dietz

Investor Relations

Phone: +49 421 2020 6426

Email: ir@ohb.de