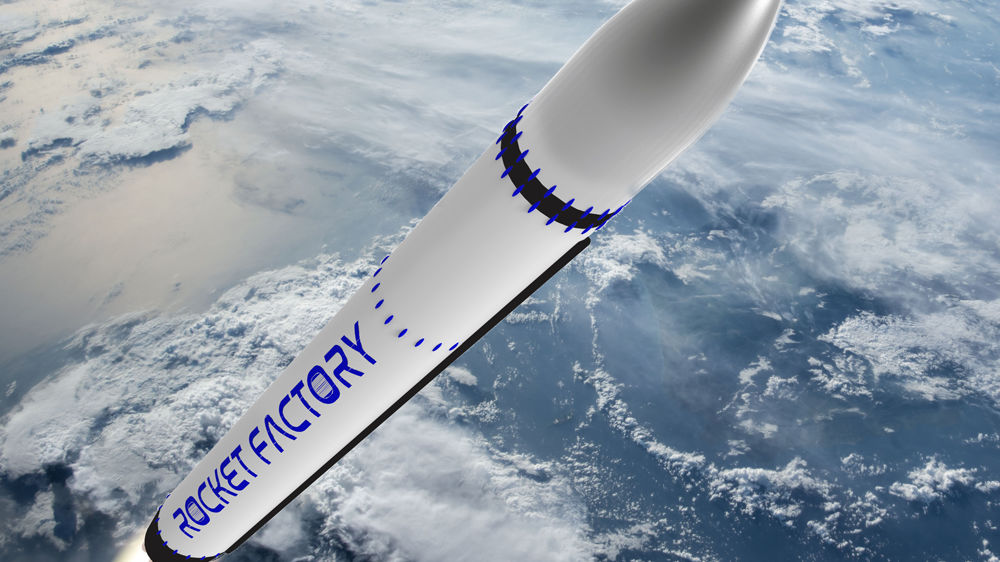

The youngest member of the international OHB family is the German company Rocket Factory Augsburg (RFA), which aims to impress the market with a self-developed mini-launcher. If the stage test, i.e. testing the engine on the ground, goes smoothly at the end of this year, there will be nothing standing in the way of the first launch at the end of 2021! This completes the OHB Group's range of services and enables it to offer "space systems from A to Z" with its own mini launcher!

1. In total, well over one hundred companies are working on Mini Launchers – three in southern Germany alone! Why will you of all companies be able to prevail in the market?

“Our aim is to provide a first-class product at affordable rates, which gives our customers tremendous flexibility in terms of time and place of launch. That’s why we like to call it a ‘mini-launcher concept’. The Rocket Factory has two decisive advantages: As a corporate venture, it has established companies such as MT Aerospace AG and OHB System AG behind it and can rely on support in the form of technology transfer or use of equipment. In addition, the OHB Group provides a certain base load with its small satellites.” Hans Steininger, CEO MT Aerospace AG

2. You not only support the young company, you also closely follow what is happening in Augsburg. Does this remind you of the time when OHB was first getting started?

“Yes, I do indeed feel transported back to the late 1990s, when the then small OHB in Bremen was, in a manner of speaking, on its way to the top. Back then, too, our motto was: smaller, lighter, more affordable – with high performance, of course! At the Rocket Factory I sense the same passion, coupled with a great deal of courage and expertise. I find the idea of supplementing the OHB Group's portfolio with our own mini-launcher very appealing.” Marco Fuchs, CEO OHB SE

3. You're considering building a launch pad. Why are the existing facilities not sufficient for the RFA?

“We believe that vertical integration of the value chain is the best way to offer an affordable and competitive launch service. This is the main reason why we need a dedicated launch site to operate with the smallest possible infrastructure and lean organisational structures. This also allows us to meet our goals of short launch times and a launch service with a complete launch service spectrum.” Alain Pajonk, Head of Launch RFA

4. You swear by a mix of New Space and the Silicon Valley approach. Why, and what does that mean in everyday operations?

“For us, it is not only the speed of the launcher that is important, but also the speed with which we achieve our ambitious goals. In this respect, the lean start-up approaches in particular are very popular with us. This means lean processes and short decision-making paths without major time losses, thanks to unbureaucratic procedures. This is also one of the reasons why we rely so heavily on 3D printing, as it shortens our production cycles many times over compared with traditional aerospace companies.” Stefan Brieschenk, Chief Operations Officer RFA

5. Ideally, you are looking for partners who manufacture for the automotive industry and want to invest in RFA. Why are you keen on this interconnection?

“If our concept works out, in a few years we will launch twenty of our mini-launchers annually. We need structural components and ten engines for each one – then only series production makes sense. A partnership with experienced manufacturing companies is one of the options we are actively pursuing at the moment, because we will need 20 tons of 3D-printed components per year alone. Of course, future customers are also very welcome, or investors who want to give us a push during the remaining development phase, including the maiden flight.” Hans Steininger, CEO MT Aerospace AG

6. The fuel tanks are welded by hand. Is that because they have to be good? And: will it stay that way?

“The fuel tanks are still welded by hand because human workers are the most flexible way to realise such a project. This is a prototype in which some seams simply cannot be welded by machine. On the basis of the prototype, we were able to gain very good insights into the design of the components to be manufactured and the welded seams. In order to build a competitive microlauncher in the future, this process will be automated as far as possible, which means shorter production times, higher repeatability and consistent quality of the welded seams.” Johann Gogesch, Head of Prototyping RFA

7. Why does it have to be a rocket engine with staged combustion?

“In contrast to traditional engines, oxygen-rich staged combustion results in less wasted energy. A traditional gas-generator cycle drives the turbopump with a fuel-rich gas that is full of soot and CO2, which is then dumped overboard. Oxygen-rich staged combustion drives the turbopump with clean oxygen gas which is then fed into the main chamber and the remainder of the fuel added to complete the cycle. Preventing the sooty and low thrust-efficiency gas being dumped overboard.” Stefan Brieschenk, Chief Operations Office RFA

8. 3D printing of the very heart of a rocket? Why?

“With 3D printing, RFA can design and manufacture rocket parts that would have been impossible until recently. This gives RFA an advantage over our competitors. We produce parts that are more efficient and have less mass, and we do all that in a fraction of the time it would take using conventional manufacturing methods. Additive manufacturing allows us to produce prototypes very quickly, test them, redesign them and re-test an improved version in a very short time.” Filipe Barreiro, Propulsion Engineer RFA

9. You are taking off into space with 500,000 hp per engine and at the same time you talk about alternative fuel that releases fewer toxic substances. How does that fit together?

“For us it is a matter of philosophy. We firmly believe that we will be the first generation to clean up more than it pollutes. That's why we have developed a fuel that you can produce yourself using ordinary DIY materials. In this way, we avoid, for example, the highly toxic hydrazine that normally drives the upper stages and satellites. In addition, we avoid the production of CO2 in all production steps as much as possible. Furthermore, many of the application examples for cost-effective launchers can be found in the field of environmental protection or the disposal of space debris. These ideas can only be implemented at all if we have easy access to space.” Jörn Spurmann, Chief Commercial Officer RFA

10. RFA is a colourful group: international, young but already with relevant experience. Where do you find the people and what experts do you still need?

“We benefit from our network in the aerospace industry and our fresh, up-and-coming and international corporate character, which attracts many applicants. ‘Rocketry' simply magically attracts candidates – not only international applicants, but also young people from the region are thrilled that there is such an innovative company in Augsburg. For hard-to-fill vacancies such as in GNC and IT, we are also very active on LinkedIn. But local institutions are also important contacts, for example to reach qualified technicians. Nowadays people are looking for a way to make a personal contribution and see their job as more than just work. This is exactly what makes RFA so interesting.” Simone Gratz, Head of HR RFA