If you want to see satellite hardware up close, you have to dress appropriately. However, your formal wear can safely stay in the closet; instead, you will need a hairnet, smock and shoe covers. The reason for this is that satellites are not manufactured in ordinary production halls, but in clean rooms. Why is that so? What kinds of things can be found in normal rooms that could damage the satellite hardware? And how clean can you get a room?

There are no completely dust-free rooms on Earth

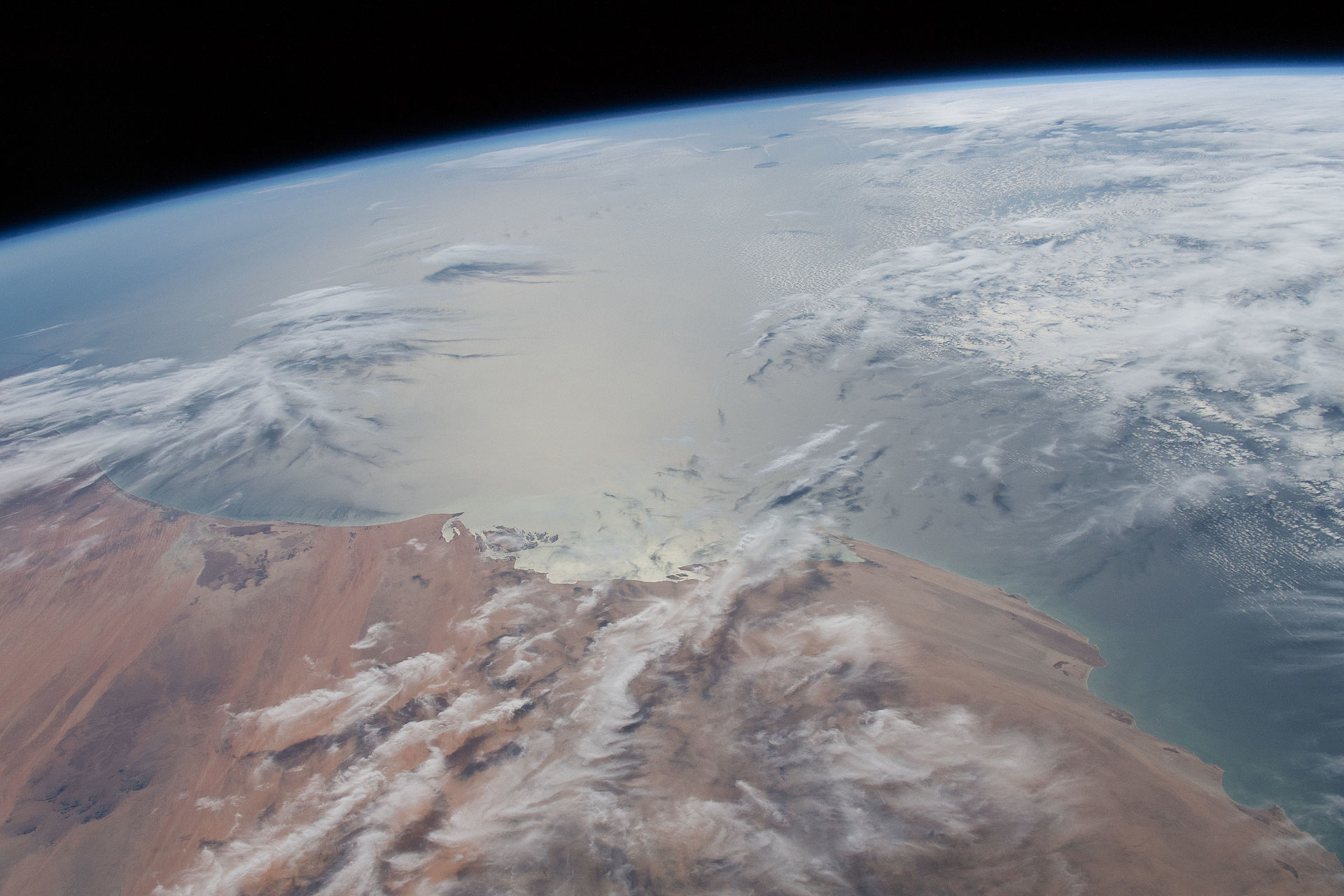

Dust is ubiquitous on Earth. In fact, it is so omnipresent that there are no completely dust-free environments. And not all dust is the same. There is an unimaginable amount of natural and man-made dust sources. Even ordinary house dust is made up of particles of different origins. They range from human and animal skin scales and hair, pollen and other plant parts to street dust and cosmic dust.

Human beings are a large source of dust

Up to 600,000 tiny flakes of skin fall off the human body every hour and even healthy people lose an average of 70 to 100 hairs every day.

In a normal room, an average of six milligrams of dust per square meter form every day

Even after cleaning thoroughly, rooms become visibly dusty again in less than a day. Human beings not only lose hair and skin scales, but also unconsciously collect particles from the environment. In addition, even normal use causes abrasion on clothing, upholstered furniture and carpets, which contributes to the formation of house dust in the form of fine textile fibres. Regular airing of rooms allows not only fresh air to enter but also pollen, soot and rock particles.

Dust reduces the reliability of satellites

Once launched into space, satellites can no longer be serviced and contaminations increase the probability of malfunctions occurring during the planned lifetime. Even a single dust particle can interrupt a circuit. In addition, the mechanics of satellites are also prone to failure due to contamination, as conventional lubricants cannot be used when operating in space. In the case of payloads, a foreign object adhering to a mirror or sensor can render entire instruments unusable. To avoid this, satellites are manufactured in clean rooms.

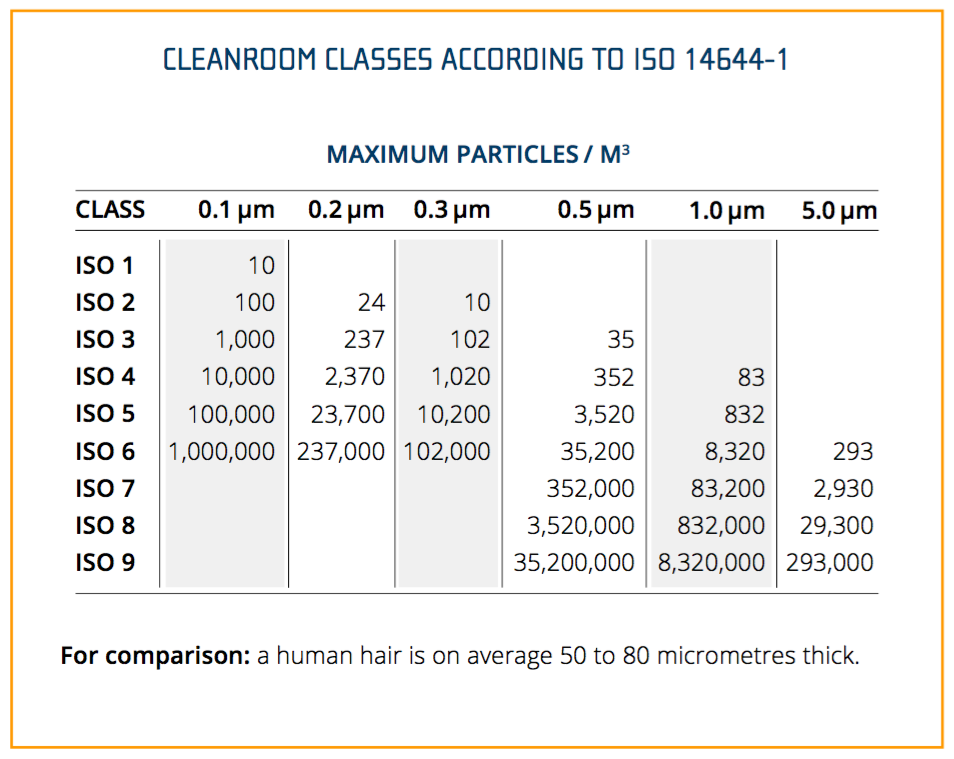

There are different standardised quality classes of clean rooms

Just as not all dust is the same, not all clean rooms are the same. Different kinds of clean rooms exist for different requirements. The classification of clean rooms is based on air purity, with the number of particles per cubic meter of air serving as a measure.

The cleanest room in the world is ten times cleaner than an ISO-1 clean room

The cleanest clean room in the world is not operated by an aerospace company, but by the Fraunhofer Institute for Manufacturing Engineering and Automation in Stuttgart. In this room, a cubic meter of air contains a maximum of only one single dust particle with a maximum size of 0.1 micrometres. This makes the air inside the room ten times purer than in an ISO 1 class clean room. The room is primarily used for testing devices and systems to be used in an ISO 1 environment, for example for the production of semiconductors and medical products.

The ambient conditions in clean rooms are kept as constant as possible

In order to avoid the uncontrolled entry of particles, clean rooms are in contact with the outside world only to the absolutely necessary extent. Pressure, temperature and humidity are kept constant regardless of the weather outside to ensure that the ambient conditions are always the same.The air is exchanged through a special ventilation and filter system. People and material can only enter the clean room through an air lock.

30 to 40 percent of all contaminations in clean rooms are caused directly by humans

Since humans cause over a third of the contamination occurring in clean rooms, clean rooms may only be entered in special clothing that primarily serves as a filter between the surface of the human body and the clean room environment. To prevent the clean room clothing itself from becoming a source of particles, it is usually made of abrasion-resistant synthetic fibres such as polyester. However, since synthetic fabrics tend to become electrostatically charged, clean room garments must be provided with a special antistatic finish. This not only serves to spare the wearer of the clothing painful electric shocks, but also to protect the products manufactured in the clean room, which can be damaged by uncontrolled discharges. In order to maintain the protection against static charge over the entire life cycle of the garment, special care procedures must be used during decontamination.

Special working materials must be used in clean rooms

Not only the clothing, but also the working materials used in clean rooms must meet special requirements. Clean room paper therefore has a special low-particle surface, and clean room pens are manufactured with particularly tightly sealed sleeves and smear-free ink to keep contamination from these utensils as low as possible. In addition, the floor and the paint on the walls must also only emit the smallest possible amount of particles. For this reason, clean room floors are usually made of synthetic resin, which is cast without joints to ensure easy cleaning. Furniture used in clean rooms must have abrasion-resistant surfaces and a design that prevents particle deposits. Moreover, it must protect the user against electrostatic charging.

Clean rooms at OHB

OHB operates class ISO 8 and ISO 5 clean rooms. A class ISO 8 clean room is sufficient for the production of satellite platforms in most cases, while payloads generally require an ISO 5 environment.