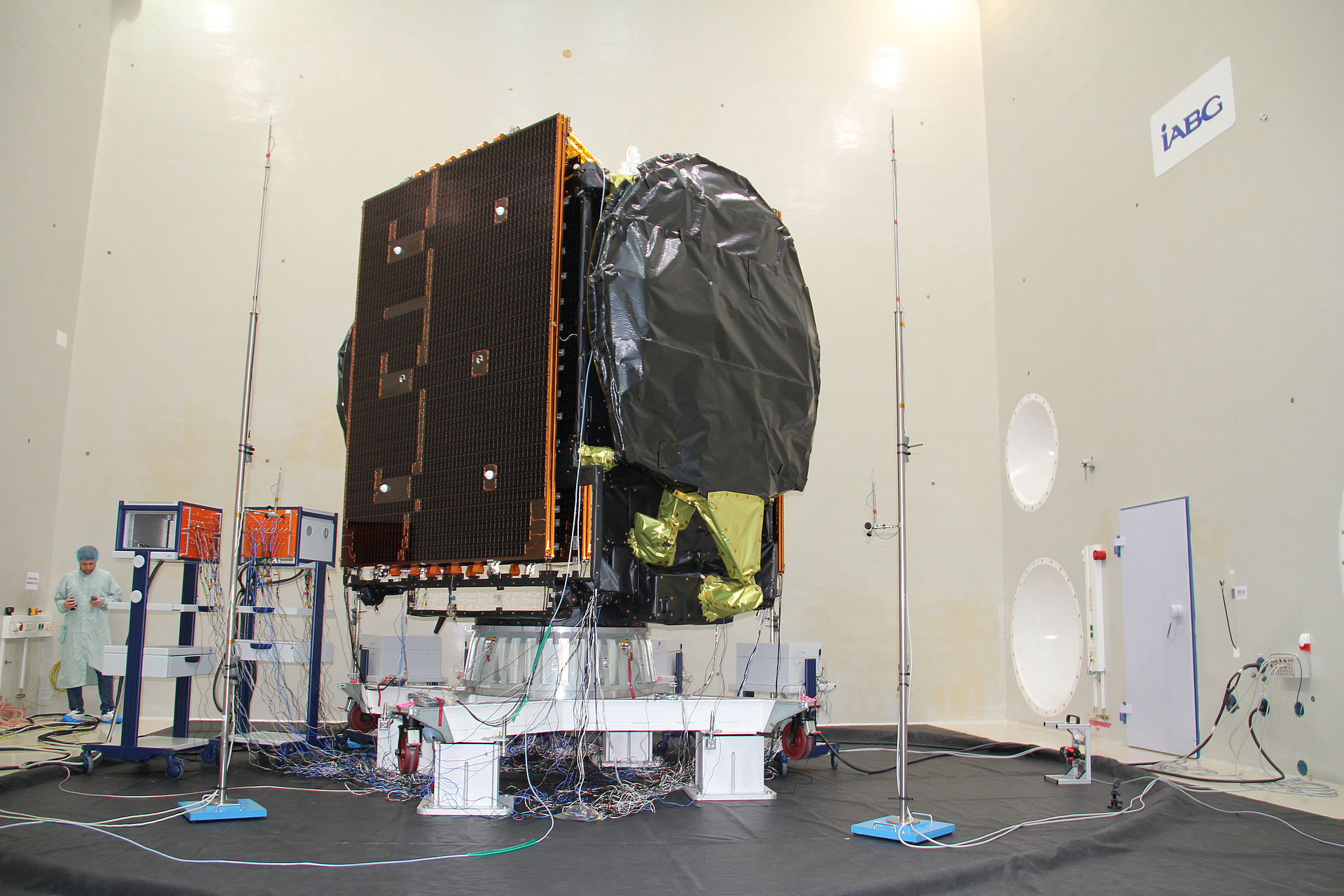

Bremen / Ottobrunn, November 13, 2018. OHB System AG, a subsidiary of the Bremen-based space and technology group OHB SE, is the principal contractor for the development and construction of the EDRS-C satellite. EDRS-C is the second node of for the European Data Relay System (EDRS), also referred to as SpaceDataHighway, which is a public-private partnership between the European Space Agency (ESA) and Airbus. The telecommunications satellite is currently undergoing several months of testing at IABG’s Space Test Centre to validate it for space flight. The SmallGeo satellite successfully completed acoustic testing on November 6, 2018.

These acoustic tests were carried out over two days to confirm that the satellite is able to withstand the stress and strain occurring during the launch phase and its journey into space. This is caused by sound waves acting on the satellite generated by the launcher’s engines as well as by aerodynamic loads.

Can the satellite withstand the acoustic loads on its journey into space?

Measuring almost four meters in height, the EDRS-C was transported to the 14-metre-high acoustic laboratory at IABG’s Space Test Centre in Ottobrunn for these tests. Three differently sized horns are integrated in a wall; during the test, the sound, which can be controlled precisely, is emitted from these horns. The satellite is configured in exactly the same way as it will be mounted on the launch vehicle. It rests on its adapter, on which it will be anchored on the launcher later on. The satellite is surrounded by several microphones. Around four hundred acceleration sensors are attached to the satellite for acoustic testing connected to just as many cables to transmit the data to the recording devices. The sonic distribution is defined in frequency ranges and varies from 30 Hz to 10 kHz. Maximum sound pressure of 156 dBA can be produced with compressed air, i.e. purified atmospheric air in a corresponding cleanroom quality. If, for example, a satellite travels into space in the upper position of the European Ariane 5 launcher, the acoustic test must produce around 143 dBA in order to simulate the loads. During acoustic testing in the 8 x 8-meter sonic laboratory, the loads impact the satellite from all sides because the laboratory, which is cast from a single piece of concrete, is sealed with a 140-ton sliding door together with a further sound-insulating door, with the result that the sound from the walls repeatedly reverberates.

Bated breaths during testing

Obviously enough, it is always exciting when the two tall gates slowly start to move and close one after the other, the compressed air then audibly flows into the chamber and testing finally commences. During testing, the teams from IABG and OHB are jointly observing the satellite response on monitors. Two cameras transmit live images of the satellite from inside the chamber: only its external thermal insulation foils, the MLI (multi layer insulation), move slightly in response to the air pressure. On other screens, vast amounts of different data are displayed in different ways. After the test, IABG hands over the data collected by the sensors to OHB’s analysis. At this moment, the OHB structural experts step in to identify any anomalies that may show up in the superimposed curves. Fortunately, they were quickly able to give the “all go”, meaning that the satellite is now able to continue on its journey through various test chambers and halls in the clean room area of the testing center with a total floor area of approx. 4,000 square meters as testing has not yet been completed.

“EDRS-C has now also shown that it can withstand the vibration and acoustic loads that occur during launch and in the pre-orbit phase free of any damage,” says a delighted Dr. Stefan Voegt, EDRS-C project manager at OHB System AG. “I would like to thank everyone involved for the great teamwork. Using large helium balloons and rail systems, we will soon be verifying that the solar panels and antennas can be released correctly in zero-g conditions. In addition, we will be proving that the payloads can achieve their specified performance and that the antennas “radiate” as planned.”

Ticket to space booked for 2019

The EDRS-C satellite will continue to undergo testing until about April 2019. Roughly five weeks before the scheduled launch date in the second quarter of 2019, it will be shipped to the launch pad in Kourou in French Guyana. An Ariane 5 launcher will then transport EDRS-C into space. OHB System AG has engineered and assembled the satellite on behalf of Airbus. EDRS-C is based on the SmallGEO platform developed by OHB under ESA’s ARTES program (Advanced Research in Telecommunications Systems).

The SpaceDataHighway is the world’s first “optical fibre in the sky” based on cutting-edge laser technology. It will be a unique system of satellites permanently fixed over a network of ground stations, with the first - EDRS-A - already in space and covering from the American East Coast to India. Each day, it can relay up to 40 terabytes of data acquired by observation satellites, UAVs and manned aircraft, at a rate of 1.8 Gbit/s.

Information on the European Data Relay System can be found on the ESA website:

http://www.esa.int/Our_Activities/Telecommunications_Integrated_Applications/EDRS

Information on the SpaceDataHighway can be found on the Airbus website:

SpaceDataHighway.airbus.com/

Information on the SmallGEO platform can be found on the OHB SE homepage

https://www.ohb.de/de/space-systems/satelliten

Contact for media representatives:

Marianne Radel

Head of Corporate Communications

Phone: +49 421 2020 9159

Email: marianne.radel@ohb.de

Contact for investors and analysts:

Marcel Dietz

Investor Relations

Phone: +49 421 2020 6426

Email: ir@ohb.de